The foundation of any sturdy and enduring structure depends on the quality of its materials. There is a vast array of materials available, and selecting the best one can be a daunting task. Phenolic boards, gypsum boards, and marine plywood are some of the best types of construction materials due to their exceptional properties and diverse uses.

In this article, we will dive deep into the unique characteristics of each material, providing you with the necessary insights to make informed decisions for your construction project. Whether you’re building a residential home, a commercial establishment, or an industrial facility, understanding the strengths and weaknesses of these materials is important to get the best out of your goal design!

Get To Know Your Boards: Composition and Manufacturing

Understanding composition and manufacturing helps ensure correct material choice, quality, durability, and proper application for effective, safe construction. Let’s learn about the composition and manufacturing processes of phenolic, gypsum, and marine plywood boards to understand their differences.

Phenolic Boards

Phenolic boards are composed of layers of paper or fabric impregnated with phenolic resin. These layers are then pressed and heated to form a solid, durable board. The manufacturing process ensures high strength and moisture resistance, making phenolic boards ideal for demanding environments.

Gypsum Boards

Gypsum boards are primarily made of gypsum, a soft sulfate mineral. The manufacturing process involves mixing gypsum with water and additives, which is then sandwiched between paper layers and dried. This results in a lightweight, easy-to-install board commonly used for interior walls and ceilings.

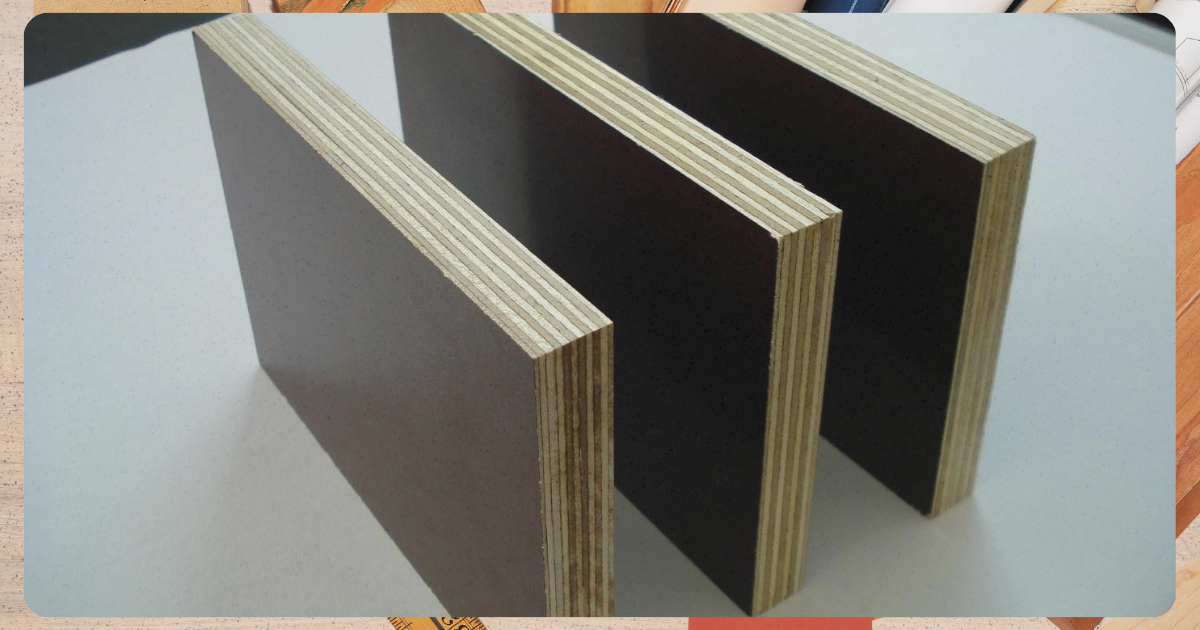

Marine Plywood

Marine plywood is made of thin layers of wood veneer bonded together with waterproof adhesive. The veneers are layered with grains at right angles and pressed under high pressure, creating a board that is highly resistant to moisture. Marine plywood is suitable for exterior use and areas exposed to high humidity.

Which Board is Which?: Types, Best Application, Pros and Cons

Knowing the types of boards and the best ways to use them ensures durability, cost-efficiency, and suitability for each specific application in DIY and construction projects. This is because while these materials are known for their durability, each is designed for different applications. Using them the “correct way” maximizes their durability and extends their lifespan.

Phenolic Boards

There are standard phenolic boards and high-pressure phenolic laminates. Due to their moisture and chemical resistance, phenolic boards are best used in high-moisture areas, exterior cladding, and laboratory countertops.

| PROS | CONS |

|

|

Gypsum Boards

Gypsum boards come in various types such as:

- Regular gypsum board/Drywall whiteboard – The standard board for general interior walls and ceilings, offering basic fire resistance. Used in applications where there is no specific requirement.

- Moisture-resistant (Green Board) – Designed to resist moisture and is ideal for use in damp or areas with high humidity.

- Fire-resistant (Type X) – This type of gypsum board has enhanced fire resistance and is designed to be used in fire-rated partitions and ceilings.

- Impact-Resistant Gypsum Board – This type of board is reinforced with glass fiber mesh, special additives and a denser core for higher durability and resistance to physical impacts.

- Soundproof Gypsum Board – This type is engineered to reduce sound transmission between rooms and improve the acoustic performance of the structure.

In general, these boards are best suited for interior walls and ceilings and are particularly valuable in fire-rated partitions due to their fire-resistant properties.

| PROS | CONS |

|

|

Marine Plywood

Marine plywood types include the following:

- BS (British Standard) 1088 marine plywood -High-quality, waterproof plywood suitable for marine environments and exterior applications.

- A-A – Premium grade plywood with both sides showing high-quality veneer without defects.

- A-B – Plywood with one high-quality veneer side (A) and one lower-grade side (B).

- B-B –Plywood with both sides of lower grade veneer, suitable for less visible applications.

- Medium-Density Overlay (MDO) – Plywood with a resin-impregnated paper overlay, providing a smooth, paintable surface.

- High-Density Overlay (HDO) – Plywood with a thick, durable resin overlay, ideal for heavy-duty applications and high wear.

Marine plywood is a versatile material that is excellent for boat building, exterior structures, and areas exposed to high humidity, thanks to its durability and water resistance.

| PROS | CONS |

|

|

Get On Board With Boards!

Phenolic boards, gypsum boards, and marine plywood each have unique compositions, types, pros and cons, and environmental impacts. Your choice should be guided by the specific needs of your project, environmental considerations, and budget constraints.

Ultimately, the best choice depends on your project’s specific requirements and environmental considerations. To ensure you select the most suitable material, consult with a construction professional who can provide expert advice tailored to your needs. Make an informed decision and invest in the right board to achieve lasting results and optimal performance for your construction projects!

References

Afyun Plywoods. (2023, June 2). What is Marine Plywood? What Are Its Various Grades? Afyun Plywoods. Retrieved August 6, 2024, from https://afyun.com/afyun-marine-plywood/different-grades-of-marine-plywood/

Dimitrova, S. (n.d.). What is phenolic plywood for construction and what are its benefits? Alsina.com. Retrieved August 6, 2024, from https://www.alsina.com/en/what-is-phenolic-plywood-for-construction-and-what-are-its-benefits/

McCoy, T. (n.d.). What is Marine Plywood – its Types and What it is Made of? McCoy Mart. Retrieved August 6, 2024, from https://mccoymart.com/post/what-are-marine-plywood-its-types-and-what-it-is-made-of/

Saint-Gobain Malaysia. (n.d.). GYPSUM BOARD – USES AND BENEFITS. Saint-Gobain Malaysia. Retrieved August 6, 2024, from https://www.saint-gobain.my/events-news/gypsum-board-uses-and-benefits