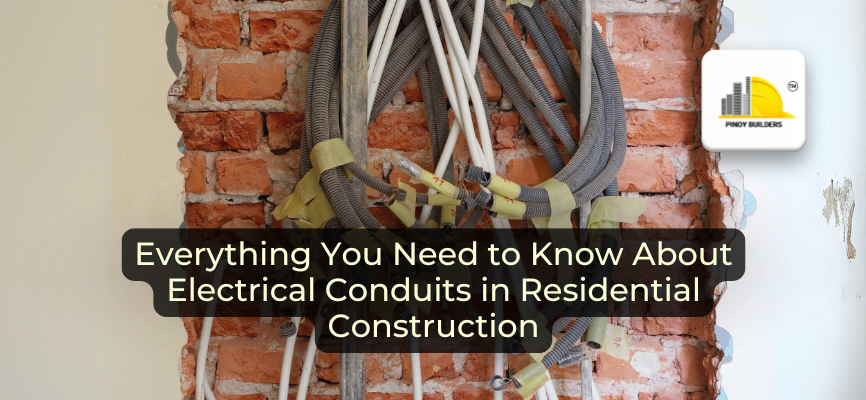

Electrical conduits are protective tubes used for electric wiring. They are necessary not only for maintaining electrical safety within an area but also for making wire routing easier for electricians.

Conduits are classified as either flexible or rigid. They are usually made out of certain construction materials such as metal, clay, or plastic. Each kind differs from one another in terms of job flexibility and its effectiveness against corrosion.

To help you understand what each type does, we have listed down the most commonly used conduits for residential environments:

Rigid Conduits

Rigid metal conduit pipes.

Rigid PVC Conduits

Rigid PVC (polyvinyl chloride) conduits are known for their toughness and high resistance against corrosion and fire damage. They can be used for most situations, including outdoor applications, underground environments, and can even be encased inside concrete.

Rigid Metal Conduits

Rigid metal conduits (RMC), offer the same advantages as its PVC counterpart, albeit using galvanized steel for maximum durability.

Intermediate Metal Conduits

The intermediate metal conduit (IMC) is a thinner, lighter version of rigid metal conduit. It is generally considered as an upgrade to RMCs, since it is more accessible in comparison.

Flexible Conduits

Flexible conduit (liquid-tight, metal).

Flexible Metal Conduits

Flexible metal conduits are, as the name implies, flexible and take on the form of a slinky tube, similar to a shower’s chrome hose. Its function is similar to the other tubes, though its flexibility and protection against vibration damage make it a notable product.

Liquid-Tight Flexible Metal Conduit

Another version of it, known as the liquid-tight flexible metal conduit (LFMC), offers all the advantages, plus waterproof plastic coating.

Electric Tubing

Electric non-metal tubing.

Electric Metal Tubing

Electric metallic tubing, or EMT, is an affordable lightweight steel tubing that is durable and easy to use. It is made out of steel and aluminum and is mostly used for indoor wiring.

Electric Non-Metallic Tubing

A plastic version of it called the electrical non-metallic tubing (ENT), is much more resistant to moisture damage and corrosion. However, it is weak when used for exposed tubing. ENTs are better suited for interior wiring.

Conduits protect the wires from malfunctioning, and protect residents from plausible electric accidents. The most important thing you should remember is that most of these are fireproof and dustproof, and are generally easy to handle.

![]()