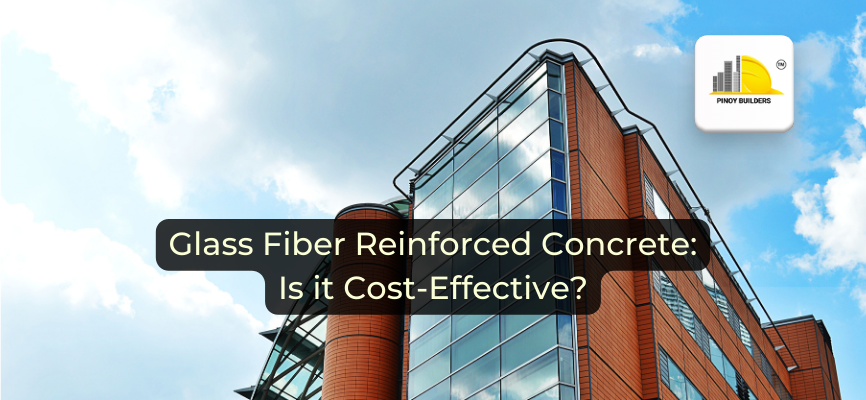

A common material used in exterior building facade panels, Glass fiber reinforced concrete (GFRC) is a composite material that is stronger but more lightweight compared to a basic concrete mix. This material has unique benefits which open many great possibilities for the construction industry. However, while glass fiber reinforced concrete comes with great features that can be beneficial in modern building projects, it is still important to determine its cost-effectivity and if it is a viable construction material option that can be used on a massive scale.

In this article, we will discuss the important components relating to GFRC, its advantages, and its disadvantages to figure out if the innovative construction material is sustainable and cost-effective.

What is Glass Fiber Reinforced Concrete?

GFRC is a type of concrete consisting of high-strength, alkali-resistant fiberglass mixed into a ceramic and concrete mix. The glass fiber blended into the concrete and cement mixture increases the load-bearing capabilities of the material. This makes glass fiber reinforced concrete more durable, with versatile components that also increase the material’s flexibility. On average, GFRC is 75% lighter and has two to four times more flexural strength than regular concrete.

In addition to this, a GFRC is lighter compared to traditional and natural materials. An artificial rock completely made out of glass fiber reinforced concrete would only weigh a fraction of a rock of its similar stature. In the infrastructure industry, this can be a truly significant benefit, especially in the landscaping industry since the transportation of a GFRC-made material can cost much less in shipping.

With its flexible, versatile, and durable nature, designers can use GFRC to recreate different architectural styles. GFRC can be molded into various textures, colors, and finishes. Because of these qualities, GFRC is commonly used to form exterior cladding panels, such as screens, panels, claddings, and other pre-cast structures.

What Are the Advantages of Using Glass Reinforced Concrete?

The advantages of using GFRC are:

• The absence of reinforcement steel makes it more resilient to exposure to salts or moisture.

• Construction firms can save transport costs because GFRC is 75% lighter than the basic concrete mix, on average.

• GFRC’s weight allows easy and rapid installation since the material can be easier to handle. The weight applied to the structure can also be reduced.

• Can increase flexibility in infrastructure design.

• Produces less waste and uses fewer natural resources.

• Has a better capacity to bear seismic loads.

• Less vulnerable to weather effects than normal concrete.

What are its disadvantages?

Despite having these amazing advantages, GFRC also possesses several disadvantages:

- It is used as a no-load-bearing wall. (The structure is not capable of supporting any other part of the building other than the wall itself/ It can not bear other structures’ load/weight.)

- Installation requires a separate anchor system.

- Larger panels need to be reinforced to add stability.

- The color of the material may fade with sunlight.

- It is more expensive than regular concrete.

Is it Cost-Effective?

Being cost-effective does not necessarily translate to low-cost or cheap products. Cost-effectiveness means that the product or service offers value in terms of value expenses.

Glass fiber reinforced concrete may cost more than regular concrete, but its advantages can help save costs and create significant benefits. Below is a rundown on what makes GFRC a cost-effective material:

- GFRC is durable and made to last. The material can withstand water, fire, seismic activity, wind, salt, and extreme temperature changes. Because of this, GFRC requires less frequent maintenance, thus reducing maintenance costs.

- GFRC is versatile. The material can be shaped into any form which allows the recreation of historical, futuristic, or any other unique designs.

- GFRC can reduce transportation and installation costs. Its lightweight design makes it easier to transport, handle, and install, making it a material that is beneficial in cutting labor and logistical costs.

- GFRC can save energy. The material can help maintain a comfortable indoor temperature and reduces reliance on HVAC systems.

- GFRC is a sustainable and environmentally friendly material. The glass fiber mixed material uses less cement than normal concrete. GFRC also produces lower CO2 emissions during manufacturing.

Glass Fiber Reinforced Concrete is gaining popularity in the construction industry because of its durability, versatility, lightweight, and design flexibility. This material offers unique advantages that make it cost-effective despite its higher cost compared to regular concrete. With this material, construction professionals and property owners alike will save money while achieving their desired design aesthetic.

References:

- A. (2022a, March 30). Everything You Need to Know About Fibre Concrete. Concrete Flooring Solutions. https://concreteflooringsolutions.co.uk/blog/fiber-concrete/

- A. (2014, January 8). Fiberglass Reinforced Concrete – Uses, Advantages and Disadvantages. Civil Engineers Forum. https://civilengineersforum.com/fiberglass-reinforced-concrete-uses-advantages-disadvantages/

- Bill Palmer, ConcreteNetwork.com Columnist

- Updated August 21, 2020. (2022, September 19). GFRC – Glass Fiber Reinforced Concrete. Concrete Network. https://www.concretenetwork.com/glass-fiber-reinforced-concrete/

- Wikipedia (n.d.) Glass fiber reinforced concrete. Retrieved from: https://en.wikipedia.org/wiki/Glass_fiber_reinforced_concrete