Because of the interest in sustainable development and new environmental regulations on waste disposal, research has been done by the Iowa State University regarding the behavior of concrete with supplementary cementitious materials (SCMs) under certain conditions. Furthermore, this was also done because while adding SCMs to cement such as fly ash, slag, etc. can improve workability, durability, strength, and overall performance, the gap in knowledge has limited its use.

These ordinary portland cements (OPC) mixed with at least one SCM are called blended cements. Blended cements have two types: binary cements (containing OPC and one SCM) and ternary cements (containing OPC and two SCMs). For the study, the researchers used OPC and 15% Class C fly ash for the binary cement. For the ternary cement, they mixed the OPC with 15% Class C fly ash and 20%, 25%, or 35% slag.

Below are the findings of the study:

Proportion of materials

It has been found that the performance of concrete varies depending on the proportion of the SCMs. For example, fly ash functions as a water-reducing agent in cement mixtures. As a result, ternary cement concrete can reach the same flowability as OPC concrete. Furthermore, fly ash replacement in binary cements generally increase paste/concrete set time compared to OPC concrete.

On the other hand, slag replacements in ternary cements can either increase or decrease set time. This would depend on the type of clinker used when compared with binary cement concrete.

Curing times and temperatures

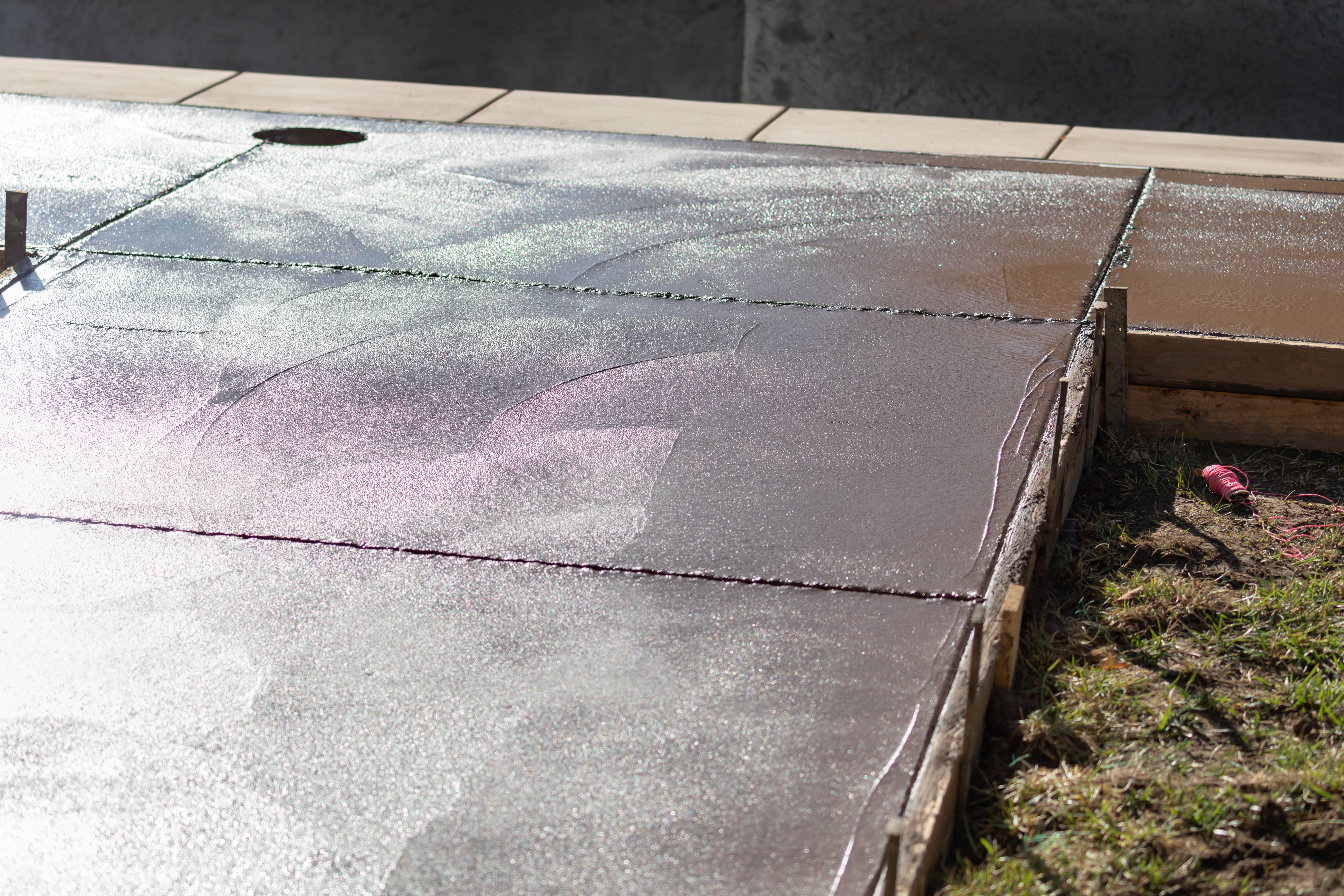

Curing is the maintenance of moisture content and temperature in concrete early on so it can develop traits that the mixture was designed to achieve. According to the study, longer curing times and higher curing temperatures may be needed the more the SCM is in the mixture.

This is especially apparent in cold weather. SCM is often characterized by slow hydration and slow setting and low-early age strength. Because of the effect of the curing temperature on the pozzolanic reaction of the mixture, trapping heat and extending curing times is ideal for SCM concrete to thrive under cold weather conditions.

Hot weather conditions

With regards to hot conditions, the study found that SCM concrete has better performance in hot conditions compared to OPC. This is because SCM concrete generally has a lower possibility of thermal cracking. This is due to the maximum heat of cement hydration in both binary and ternary cement concrete decreasing with the amount of SCM replacements.

Aside from that, under hot weather conditions (90° F), both the binary and ternary cement concretes have a slightly longer set time than OPC concrete. This then permits sufficient time for concrete placing and finishing.

Lastly, under the same conditions, the binary and ternary cement both have comparable strength at the age of about 7 days. The ternary cement concrete has higher strength at 14 days.

Based on this study, we can conclude a couple of things:

- Blended cements, formed through additions of SCM, have improved concrete workability, lower possibility of thermal cracking, improved concrete durability and strength, and reduced overall concrete cost.

- Blended cement works better in both hot and cold weather conditions.

- Blended cement is much more environmentally-friendly.

There are a lot of benefits for blended cement use, from it being much better performance-wise to also being a good alternative to more environmentally harmful cement. Indeed, the SCMs used in blended cement like Class C fly ash are there to improve workability and reduce cost. This is why more studies need to be done to ensure that its benefits are spread to people in the industry so its use can be more widespread. Once more professionals start using it, there will be an increase in stronger, long-lasting construction projects and structures.

Fortunately, Holcim Solido is now in the Philippine market. This blended cement is perfect for all road and mid-rise construction. Aside from this, Holcim Solido also abides to the Blended cement advantages, namely:

- Durability

- Low heat

- High strength

- Better workability

- Environment-friendly

Holcim Solido ensures that these Blended cement advantage points are present and consistent all throughout. Made from top materials and designed for sustainability, Holcim Solido is the cement of the future today.

![]()