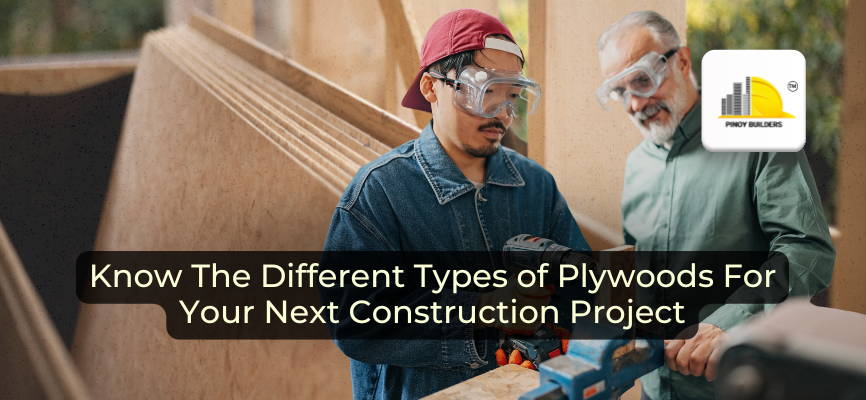

Plywood has been a go-to material in Filipino homes, construction, and DIY projects for years. It’s affordable, versatile, and easy to find, making it a favorite among builders and homeowners. But with sustainability becoming a bigger priority, knowing your plywood options and using them responsibly matters more than ever.

Eco-friendly choices like plywood can help minimize the environmental impact of construction. In this article, we’ll explore why many Filipinos continue to rely on plywood, diving into what makes it a practical and durable option for various building projects.

The Versatility of Plywood in Filipino Homes and Construction

In the Philippines, plywood is a staple in homes, businesses, and DIY projects. It’s used for everything from flooring and roofing to furniture and cabinetry. What makes it so popular is its affordability, versatility, and how easy it is to work with. Whether you’re cutting, shaping, or finishing it, plywood adapts to both large construction jobs and small creative projects.

Plywood is available at most hardware stores, so it’s easy to find. It’s also tough—offering strength and stability without costing you a fortune. Whether you’re building a house, upgrading a space, or crafting a custom piece, plywood’s flexibility and budget-friendly appeal make it a top choice.

Types of Plywood for Your Next Project

When it comes to plywood, choosing the right type for your project is essential for durability, functionality, and safety. Below are some common types of plywood you’ll come across in construction:

1. Marine Plywood

Image from Fushi Wood Group

Marine plywood installed in a bathroom

Designed for high-moisture environments, marine plywood is the go-to choice for projects that involve exposure to water, such as boats, docks, and outdoor structures. Its resistance to water and humidity makes it perfect for these applications, ensuring long-term durability.

2. Softwood Plywood

Image from Vinawood Vietnam Plywood

Softwood plywood installed as roofing

Made from pine, fir, or spruce, softwood plywood is commonly used in construction projects. When strength is required but appearance isn’t the primary concern, it’s ideal for roofing, subflooring, and structural applications.

3. Hardwood Plywood

Image from Plywood Project

Hardwood plywood is used as material for indoor furniture.

For projects that require strength and a smooth, polished finish, hardwood plywood is the preferred option. Furniture making, cabinetry, and other high-end finishing projects often use it. Hardwood plywood is more durable than softwood plywood and has a finer, more attractive surface.

4. Exterior Plywood

Image from SPAX US

Exterior plywood works well in outdoor applications such as property fences.

If your project is exposed to rain or humidity, this is the best option.

Exterior plywood is designed to withstand the elements because it is made with waterproof glue to resist moisture and harsh weather conditions. It’s commonly used for outdoor structures like siding, fences, and garden furniture.

5. Interior Plywood

Image from Build Show

A home construction project uses interior plywood as wall paneling.

For indoor applications, interior plywood is the best choice. Furniture, cabinets, and paneling use interior plywood in areas with minimal moisture exposure. Unlike exterior plywood, it doesn’t have waterproof adhesives, so it’s best suited for dry environments.

6. Structural Plywood

Image from Complete Building Solutions

The structural plywood has been installed as ceiling beams.

The construction of this type of plywood prioritizes strength and stability. Load-bearing applications commonly use it in walls, beams, and flooring. Its durability makes it essential in construction.

7. Fire-Retardant Plywood

Image from Tague Lumber

Commercial building using fire-resistant plywood underneath the external facade.

Fire-resistant chemicals have treated this type of plywood to help prevent the spread of flames. Commercial buildings or spaces that require extra fire safety measures, like schools or hospitals, typically use it.

8. Veneer Plywood (Decorative Plywood)

Image from Ilpocolo Design

Veneer Plywood used on interior walls.

Veneer plywood is the ideal choice for projects that require a refined, luxurious appearance. It features a thin layer of premium wood, like walnut or mahogany, giving it a stylish finish. People often use it for decorative furniture, wall paneling, and interior design elements that demand a refined appearance.

Choosing Eco-Certified Plywood for Sustainable Construction

Making sure plywood meets industry standards is crucial for safety, durability, and overall construction quality. In the Philippines, the Department of Trade and Industry’s Bureau of Philippine Standards (DTI-BPS) enforces strict regulations through Department Administrative Order (DAO) No. 20-06. Before entering the market, this rule mandates the certification of all locally manufactured and imported plywood.

Manufacturers need to secure the Philippine Standard (PS) Quality Certification Mark License, proving their plywood meets national standards. Importers, on the other hand, must source their products from foreign manufacturers with valid PS licenses. This regulation ensures substandard plywood doesn’t make its way into the market.

DAO No. 20-06 requires specific product markings, such as the following, to help buyers identify compliant plywood:

- Registered trade name or brand name

- Business name and address of the manufacturer or importer

- Country of origin

- Type of plywood (softwood or hardwood)

- Bonding class (1, 2, or 3)

- Thickness in millimeters

- Formaldehyde emission level and star rating (as per PNS 2103:2017)

- Lot or batch number

- PS Mark with license number

These markings ensure traceability and serve as a guide for consumers when choosing plywood that meets safety and performance requirements. The enforcement of quality certification helps maintain industry standards and provides builders and homeowners with durable and reliable construction materials.

Efficient Usage and Waste Reduction Practices

Reducing waste is an important part of responsible plywood use. Here are some tips to minimize waste and make the most of your materials:

1. Smart Cutting

- Plan and measure carefully before cutting plywood sheets

- Cut plywood according to your exact project requirements to reduce leftover material

- Remember the rule: Measure twice, cut once

2. Upcycling Leftover Plywood

Upcycling prevents waste and gives you the opportunity to add unique touches to your project. You can repurpose small off-cuts into creative and functional items:

- Picture frames

- Shelves

- Planters

3. Repurposing Larger Pieces

Repurposing plywood helps reduce waste and your environmental footprint. Larger leftover plywood sheets can be used for new materials in future projects such as:

- Wall paneling

- Workbenches

- Outdoor furniture

These simple practices can go a long way in minimizing plywood waste and making your projects more sustainable.

Non-Toxic Sealants, Glues, and Finishes for Safer DIY Projects

When finishing your plywood project, it’s important to consider the materials you use. Many traditional sealants, glues, and finishes contain harmful chemicals that can release toxic fumes, affecting both your health and the environment. Fortunately, safer, non-toxic alternatives are available:

Health and Environmental Impact

- Traditional sealants, glues, and finishes often contain chemicals that release toxic fumes

- These chemicals can harm your health and negatively affect the environment

Safer Alternatives

Safer alternatives help minimize harmful emissions and contribute to a healthier environment. Eco-friendly sealants and glues are made from natural ingredients, such as:

- Plant-based oils

- Water-based solutions

Using non-toxic finishes also helps create safer environments for everyone involved in the construction process, especially in residential or indoor settings. Whether you’re a DIY enthusiast or a professional builder, choosing safer materials for your projects can make a big difference in both quality and health.

Making Sustainable Choices for Your Next Project

When starting your next construction or DIY project, consider using eco-certified plywood, reducing waste, and choosing nontoxic finishes. These simple steps promote sustainability, cut down on environmental impact, and create healthier spaces. As eco-friendly options gain popularity, making these choices benefits both your project and the planet.

For more details on the Philippine Standard (PS) Quality Certification for Plywood, visit the BPS Standards and Conformance Portal at www.bps.dti.gov.ph.

References

Bureau of Philippine Standards. (2021, February 8). DTI-BPS now requires product certification for plywood – BPS S&C Portal. Bureau of Philippine Standards. Retrieved April 3, 2025, from https://bps.dti.gov.ph/press-releases/28-2021/262-dti-bps-now-requires-product-certification-for-plywood

PLYCO. (n.d.). The Differences Between Structural and Non-Structural Plywood. PLYCO. https://blog.plyco.com.au/the-differences-between-structural-and-non-structural-plywood

Vinawood Vietnam Plywood. (2020, November 20). 20 Types Of Plywood Used In Interior And Exterior. Vinawood Vietnam Plywood. Retrieved April 3, 2025, from https://vinawoodltd.com/blogs/news/20-types-of-plywood-and-grades-used-in-interior-and-exterior-with-pictures