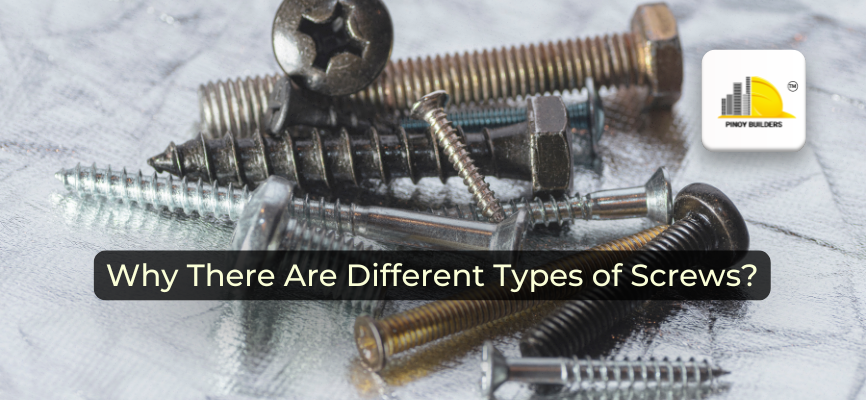

Through the years, various manufacturers have sought to improve screw designs in different ways, from improving their ability to fasten with a driver tool to preventing cam-outs or stripping from excessive torque. Numerous variants exist to create a perfect industry standard design, yet the world can’t seem to decide on using just one.

There are many reasons for this. Some due to manufacturing issues, others because of licensing agreements. Listed below are a few of these reasons that might give an answer to the age-old question of why are there so many screws.

Common Screw Types

Before we begin, let us have a short recap on the common types of screws being used in the industry and home projects today.

Slot Head

Flat Head Screw Drive

Flat certainly has done justice for construction throughout the centuries. The flat head screw is iconic in every way, though these days not a lot of modern builders are a fan of it for coming off as being too obsolete and flimsy to use compared to its counterparts. However, its simplicity separates it from its predecessors as its screwdriver has and is still being used for related purposes such as opening paint cans and taped-up packages.

Flathead screwdriver (left) and slotted screw (right).

Phillips-Head

Cross Head Screw Drive

Contrary to popular belief, the Phillips-Head isn’t actually named after the inventor, but rather the owner of the company that bought the rights to the design. The Phillips-Head is superior to the flat-head for having a design that allows driver tools to fasten itself to the screwhead more securely.

Phillips-screwdriver (left) and Cross Head/Phillips-head screw (right).

Robertson

Square Screw Drive

Sometimes known as the square screw drive, the Robertson screws are known for its ease of use as it features a tapered square drive that makes it self-centering and provides ample slip-resistance.

Robertson bit (left) and square screw (right).

Spanner

Security Screw

Spanners are also known as pig nose drives because of its peculiar two-hole design resembling a pig’s nose. It is a security drive that focuses mainly on using an unconventional drive style, making it perfect for public facilities such as screwed-in furniture or public restrooms. However, another reason spanners are unconventional are due to the fact that its two-hole design makes bits susceptible to breakage if extreme stress is forced onto it during installation.

Spanner screwdriver (left) and spanner screw (right).

Torx Screw Drive

Star Screw Drive

The star-like design makes it slip resistant, helping it withstand higher torques while limiting potential screw damage. Torx screws are often utilized for the manufacturing of computer electronics and automobiles, with some utilizing a different variants and successors of the original design for security reasons.

Torx screwdriver (left) and torx screw (right).

Now that you are all caught up, let’s move on to an in-depth look at why they and so many other variants exist. Starting off with the topic of efficiency, we have cam-outs and screw-specific usage.

1.) Cam-outs

Cam-outs refer to a screwdriver or a power tool slipping away from a screw head while it is being driven into a surface. Phillip-head screws are susceptible to multiple cam-outs due to its tapered design, while other designs minimize the probability of such accidents to an extent.

Cam-out diagram courtesy of FACOM

Common causes of cam-outs:

The wrong screwdriver/bit size for the job

Using a soft or worn out screw head

Not enough downforce is applied when drilling the screw through a surface

Drilling on a surface that is too hard for the screw or the fastening device

Experts encourage changing to more secure screw types if cam-outs become too common during a job. In assembly-lines and manufacturing businesses, speed is crucial. Minimizing mistakes such as this makes a huge difference in industries.

A close up of a Hard Disk Drive. Torx and spanner screws are mainly used in electronics manufacturing.

Most types are superior to the slotted design in terms of user comfort. While flat heads are cheap and good for general projects, they have a flimsy feel to them that would make one wonder why they didn’t just invest in a Phillips-head or a Robertson.

2.) Patents and Licenses

Speaking of the Robertson, one example of a screw drive making a huge difference in an industry is the squarehead screw. Henry Ford of the Ford Motor Company found that the effectiveness of the squarehead in the production line of producing Model T cars saved him two hours of work for each vehicle.

An old photo of one of the Model T Ford factories from the past. Photo courtesy of Driving

Sadly due to licensing disagreements, the Ford Motor Company decided to make a deal with Henry Phillips of the Phillips-head screw instead. This cemented the Phillips-head’s popularity in the US while the Robertson design remains as Canada’s main screw.

Other patent or licensing issues mainly fall under the tamper-proofing category, which are held up by large companies looking to manufacture secure products.

3.) Tamper-proof purposes

For security reasons, some expensive products such as smartphones and similar gadgets use unique screw types to dissuade people from opening their phones. While the official excuse is to protect the user from unintentionally damaging their property, a popular reason that has been circulating online is that it is so people will use licensed repair shops rather than cheap general tech repair alternatives.

It also prevents people from tampering with public and private property. The spanner is particularly known for this feature, and the common misconception that it is difficult to obtain a spanner screwdriver means people are less likely to mess with said properties.

4.) Rarity of particular bits, screws, and screwdrivers

Supply and demand meet screw quantity and size. Some screws are rarer in some areas, while others are practically devoid of the type they need. With the advent of the internet, buying specific screws and bits have become easier. While the Robertsons are starting to gain traction in the US at present, many users and small manufacturers are just more comfortable with using Phillips and slot head screws.

On a lesser note, there’s the matter of style. Some go after slot heads and spanners for the subtlety of their looks, while others go for the Torx screws because of their niche starfish detail.

There are plenty more reasons out there, but as mentioned before, it is a matter of people making better designs through the decades in the hopes of making an industry standard screw. The more variants enter the market, the more niche it becomes unless adopted for tamper-proof reasons. Either way, the industry still values the flatheads and the Phillips-heads in spite of their quality when compared to the others. After all, when it comes to DIY tinkering, your best bet is to buy a multi drive from your local hardware store to help you with all your screwdriving needs.

![]()